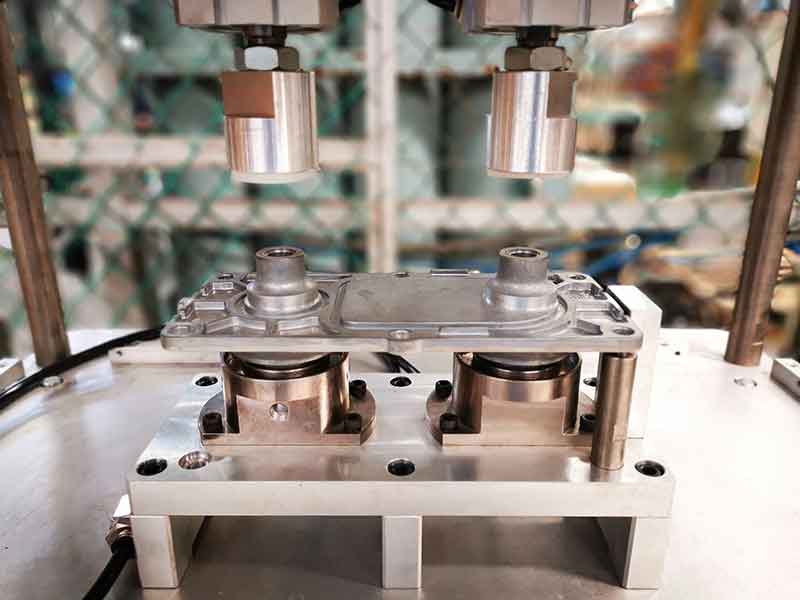

Diecasting is the utilization of molds, known as dies. Dies are created with high-quality steel in order to stand up to the tough conditions encountered in the casting process. Die designs are made precisely, usually incorporating elaborate details and precise tolerances to ensure that the finished product is accurate. The process of diecasting involves melts of metal - commonly zinc, aluminum or magnesium is injected into the dies at extreme pressures. This rapid injection and hardening results in products with excellent dimensional stability and a polished surface, which reduces the need for further cutting or polishing. The high precision of dies allows for the production of complex geometries that are difficult or impossible for other manufacturing methods.

One of the primary advantages of diecasting is the ability to manufacture parts with incredible dimensional precision and flawless finishing on surfaces. This is because high-pressure injection makes sure that every detail of the mold is replicated and the result is parts which meet the strictest tolerances and need minimal or any post-production effort. This level of precision is particularly beneficial for creating complex geometries and fine details that might be difficult or impossible to achieve in other manufacturing methods. Additionally, the repeatability of diecasting allows it to be used for large-scale production, ensuring uniformity across a large number of parts. The effectiveness of this process can also result in significant cost savings, as it reduces both material waste as well as labor expenses.

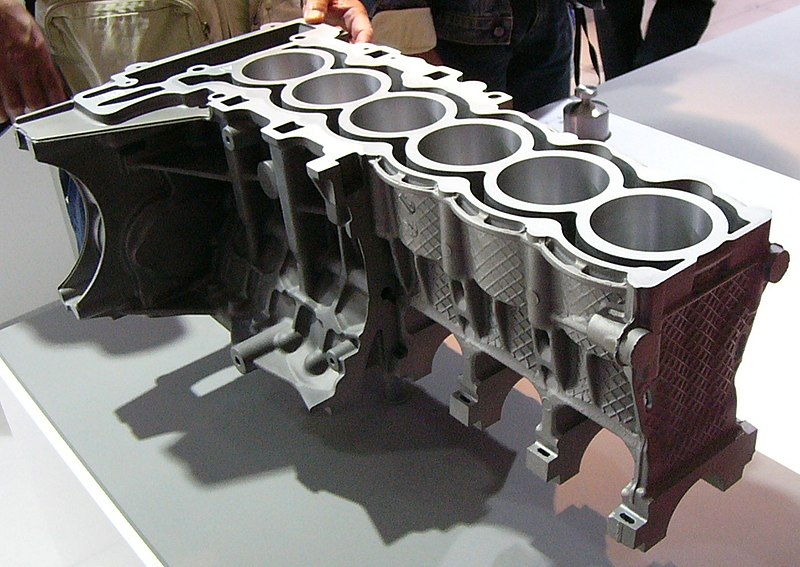

Diecasting is also a great option in terms of the mechanical properties and performance. Diecast components are known as durable and strong, which are essential characteristics for components used in challenging applications. Fine-grain formation that occurs in the process of rapid cooling metal is a key factor in these properties that make diecast products suitable to be used in highly stressed environments. Additionally, diecasting permits the inclusion of thin walls as well as complex components without harming the strength of the item. This capability is particularly advantageous for aerospace and automotive industries, where reducing weight and retaining structural strength is essential to improve fuel efficiency and overall efficiency. To obtain more information please go to www.senadiecasting.com.my/

The selection of the materials used in diecasting has a significant impact on the characteristics and the performance of the finished product. Aluminum is the most popular material because of its superior strength-to-weight ratio, corrosion resistance, along with its excellent electrical and thermal conductivity. This makes aluminum the ideal material for aerospace and automotive applications in which weight reduction is essential. Zinc alloys have high strength and ductility. This makes them appropriate for products that need fine specifications and durability. Magnesium alloys have the tiniest weight of steels that can be used for structural purposes, giving the advantage when weight reduction is crucial. Copper alloys are used less frequently they are highly valued due to their superior electrical conductivity and the resistance to corrosion. Each one of them has its own advantages making it possible for manufacturers to pick which one is best suited to the specific requirements of their application.

Diecasting is the pinnacle of technology for manufacturing, providing a blend of precision, efficiency, and versatility unlike other manufacturing processes. The ability to create sophisticated, high-quality parts with exceptional mechanical properties makes it a necessity in a variety of industries, from automobile to consumer electronic products. The efficacy and efficiency savings that diecasting offers prove its effectiveness in high-volume manufacturing. Its flexibility ensures that it can meet the demands of contemporary manufacturing. As companies continue pushing limits of innovation as well as performance, diecasting will be a vital tool helping to advance technology and facilitate the creation of innovative products which shape the world.